Powering your adventures with lithium batteries is a game-changer. But with great power comes great responsibility. A specialised lithium battery fuse isn’t just an optional extra—it’s the critical guardian of your entire electrical system. This guide will walk you through everything you need to know to stay safe and protect your investment.

Lithium batteries pack an incredible amount of energy into a small space. Unlike older lead-acid batteries, they have an extremely low internal resistance. This means that if a short circuit occurs, they can release a catastrophic surge of current almost instantaneously—thousands of amps in a fraction of a second.

This isn’t a gentle overload; it’s an explosive event that can vaporise wiring, melt components, and generate enough heat to cause a thermal runaway fire. The primary job of a lithium battery fuse is to act as a sacrificial weak link, deliberately blowing in a controlled manner to stop this deadly surge dead in its tracks. Think of it as the most important piece of safety equipment in your system.

A lithium battery fuse ‘Primary Fuse’ is a safety device specifically engineered to handle the unique dangers of high-power lithium batteries. While it works on the same basic principle—a metal element that melts under excess current—its critical feature is an ability to possess a very high Interrupting Rating (or AIC – Ampere Interrupting Capacity).

This rating is the maximum fault current the fuse can safely stop. To achieve this, these fuses use robust construction with materials like sand or ceramic filler to instantly quench the powerful electrical arc created when interrupting a massive short-circuit.

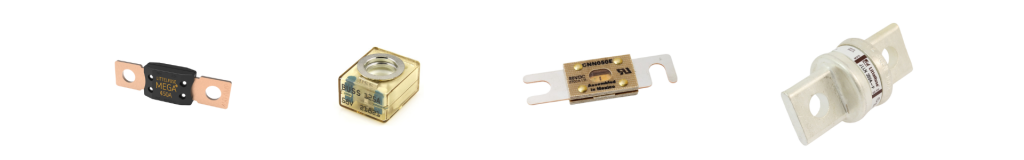

The key specification is its High Interrupting Rating (or AIC – Ampere Interrupting Capacity). This is the maximum fault current the fuse can safely stop. Standard fuses used for Lead-Acid batteries typically have a low interrupting rating. Such as a MEGA or MIDI fuse. Lithium battery banks require a more robust fuses designed to withstand and extinguish the immense electrical arc that forms when it interrupts the incredibly high currents a lithium battery can deliver. Without this high rating, a standard fuse can fail catastrophically, essentially fail in a ‘closed-circuit’ scenario by the arc in the fuse welding the fuse together and allowing the current to still flow rather than break in an ‘open-circuit’ stopping the flow of current immediately.

You cannot re-use the MEGA or MIDI fuse from your old AGM/Lead-Acid system. This is a common point of confusion. A standard MEGA fuse is completely inadequate for protecting large capacity lithium batteries.

The problem isn’t the fuse’s ampere rating (e.g., 100A), but the much less known Interrupting Rating. If the battery was accidentally short-circuited by spanner across the busbars for example.

A lithium battery can discharge current so high and fast that it can vaporize the element inside a standard MEGA fuse before it has time to blow. This can turn the fuse into a conductor, causing a catastrophic failure where the circuit is never broken.

| FEATURE | Standard MEGA Fuse | Lithium Battery Fuse (e.g., Class T) |

|---|---|---|

| Interrupt Rating | Low (e.g., 2,000A) | Very High (e.g., 10,000-20,000A) |

| Response to Fault | May vaporise, failing to break circuit | Reliably blows and safely extinguishes the arc |

| Construction | Simple plastic & metal strip | Robust, ceramic case with sand or filler to quench arc. |

Think of a fuse as a safety guard for the heavy-duty cable that connects your device to the rest of your system. Its main job is to stop that cable from overheating and causing a fire if something goes wrong. Picking the right one is simpler when you understand a few key terms.

This is the number printed on the fuse, like “100A” or “200A”. It’s the maximum amount of power the fuse can handle all day long without blowing.

Not all fuses blow instantly. A “slow-blow” fuse is like a speed bump—it allows short, powerful bursts of energy to pass through without reacting. This is perfect for devices like inverters that need a big jolt of power to start up.

Why it matters: If your fuse blows every time your fridge or inverter kicks on, you probably need a fuse that can handle these brief, high-power surges.

Fuses are designed for specific voltage systems. You must match the fuse to your battery voltage.

For 12V or 24V systems, a standard 32V DC fuse is perfect.

For 48V systems, you need a fuse rated for 58V or higher to work safely and effectively.

This is the fuse’s most important superpower: its ability to safely stop a massive, dangerous short-circuit. It is a requirement for this figure to printed on the cover of the fuse. If your fuse doesnt have this printed on its label its time to change to a reputable branded fuse.

The Problem: A short circuit can unleash a huge, instant surge of power—thousands of amps—from your battery. A weak fuse might melt shut or even explode, failing to stop the current from flowing.

The Solution: A high-quality fuse with a high “AIC” rating is built to contain and stop this short-circuit safely and preventing a fire. This is especially critical for powerful lithium (LiFePO4) batteries, which can deliver a much larger short-circuit surge than traditional lead-acid batteries.

A MEGA fuse is a type of high-amperage blade fuse designed for DC (Direct Current) electrical systems. They are typically rated for very high currents, commonly ranging from 40A to 500 Amps. Primarily designed for 32V DC systems, making them suitable for most 12V and 24V vehicle and marine applications.

Mega fuses are used as main circuit protectors in high-current DC applications. Their job is to protect the wiring from melting and causing a potential fire in the event of a dead short or a huge current overload.

Common applications include:

Vehicle Main Battery Protection: Protecting the main cable running from the battery (AGM, GEL, Lead-Acid) to the starter motor and primary distribution fuse box.

High-Power Audio Systems: Protecting the main power cable running from the battery to a high-wattage amplifier.

Winches and Hydraulic Systems: Protecting the circuits for high-draw motors.

DC-DC Chargers and Inverters: Serving as the main overcurrent protection for the large cables feeding these devices.

Marine Engine Bays: Protecting main engine and generator circuits.

A good quality MEGA fuse generally has an AIC Interrupt capability of 2000A. NOTE: This type of fuse is not sufficient to clear the large fault currents potential created by Lithium Batteries in a dead-short scenario.

Ideal for: Motorhomes, caravans, small boats and any application using lead-acid chemistry – NOT not suitable for use with (LiFePO4) Lithium batteries due to their slow blowing properties.

ANL fuses are a common and popular choice in 12v automotive systems and are typical designed for general loads and chargers in a system.

ANL fuses are well-suited for protecting circuits against over currents and moderate short circuits. There are a range of ANL fuses designed for harsh marine environments with higher AIC Interrupt Capacity of maximum 6000A. If using for our smaller DIN range of batteries up to 175ah make sure you use a high quality ANL fuse with an AIC rating of 6000A.

Ideal for: Marine, Motorhomes, Campervans and Caravans, small boats and any application using lead-acid batteries – NOT not suitable for large lithium battery systems above 175ah ARCTICXTREME model. With larger lithium batteries the AIC rating increases. MRBF is recommend up to 300A there after we recommend Class-T fuses to be placed within 150mm of the positive terminal.

Purchase ANL Fuse & holder kit here

The MRBF (Marine Rated Battery Fuse) was designed and certified for harsh marine environments. Offering compact, high-amperage, and high-interrupt-capacity circuit protection. It is specifically designed to mount directly onto a battery terminal to protect the entire cable from the battery to the fuse, offering maximum protection by eliminating any unprotected cable. Its design is ignition-protected, making it safe for use around petrol engines.

For harsh marine environments, the EATON/BUSSMANN range manufactured for Bluesea Systems . This fuse and holder assembly offers IP65 protection in a robust and compact device. Bussmann offer a range of fuse protection from 30A to 300A and most IMPORTANTLY with the high 10,000A interrupt capacity at 14V DC. Which means they are engineered to handle the potentially high fault currents that can be generated in lithium batteries.

This makes them the perfect, fully-protected fusing solution for compact installations when using LithiumPro’s DIN-sized ‘Drop-in-Replacement’ batteries for the 105 ULTRAVOLT or the 175 ARCTICXTREME and 280 SEATBASE models. For Lithium batteries larger than 300A we recommend the gold standard for Lithium a Class-T Fuse which are capable of protecting short circuit currents of up to 20,000A

Ideal for: Marine, Solar, Campervan, Motorhome and Caravan Lithium systems.

Purchase MRBF fuse & holder for DIN Batteries or MRBF & Fuse holder only here.

The Class-T is ideal for heavy-duty lithium battery systems, the Class T fuse delivers uncompromising protection. It combines a very fast reaction time with an extreme interrupt rating (>20,000A), making it the only choice for containing the high fault currents of large lithium banks.

Engineered by global leaders in circuit protection like Siemens, Bussmann, and Littelfuse, the Class T fuse is built for the extreme demands of high-power, low-voltage DC systems (up to 125V).

With ratings up to 800A and unparalleled interrupting capacity, it is the non-negotiable cornerstone of a safe, high-power lithium setup. That’s why LithiumPro Energy mandates a dedicated Class T fuse on every large 12V/24V battery we sell.

Suitable for all LithiumPro battery ranges requiring Best-in-class protection for their power system. If space permits we recommend for the 280 SEATBASE, but is mandatory for the 460 ENDURAVOLT, 628 MEGAVOLT & 24V 280 POWERHAUS models.

Ideal for: Large off-grid solar systems, electric vehicle conversions, marine and industrial applications.

Purchase Class T – BEP Fuse & fuse holder Kit.

Your system will use a range of fuses from blade fuses to MIDI and MEGA fuses to protect the loads. However, this article is aimed at sizing a primary Lithium battery fuse.

Sizing your fuse correctly is crucial. It must be large enough to handle normal operation but small enough to blow quickly in a fault.

The fuse’s in your whole system are design to protect the cable from overheating. So always ensure you DO NOT overate your fuse for the current carrying capacity of your cabling.

Determine all the continuous loads on your system that can be present at any one time. I.e. your system’s Maximum Continuous Load (Amps): Find the highest combined continuous current your system will draw.

Example: A 2000W inverter on a 12V system. 2000W / 12V = 166.7 Amps. This is your continuous load from your inverter.

Add a Safety Margin (NEC Rule): Multiply your maximum continuous load by 1.25 (125%).

Example: 166.7A x 1.25 = 208.3A. This accounts for continuous usage and prevents nuisance blowing.

Select the Next Standard Fuse Size Up: Choose the closest standard fuse rating that is equal to or greater than your calculated value.

Example: A 225A fuse is the correct choice. NOTE: Be sure to add up all your continuous loads.

Quick-Reference Chart:

For a 1000W inverter on 12V: (1000W / 12V) * 1.25 = 104A -> Use a 125A Fuse

For a 2000W inverter on 12V: (2000W / 12V) * 1.25 = 208A -> Use a 225A Fuse (Victron recommends 300A for their 2Kva Multiplus)

For a 3000W inverter on 12V: (3000W / 12V) * 1.25 = 312A -> Use a 350A Fuse (Victron recommends 400A for their 3Kva Multiplus II)

Important Disclaimer:

This is a general guide only. Always check your specific inverter manual for maximum surge current and recommended cable/fuse sizes. Never fit a fuse larger than the continuous current rating of your cable. If in doubt, ask a qualified auto-electrician – or take advantage of our free system-design service when you buy a complete off-grid package from LithiumPro. Just drop us an Email here

Installation is straightforward, but safety is paramount.

Location is Everything:

The fuse must be installed on the positive cable, as close as physically possible to the battery terminal. AYBC rules state within 150mm of the positive terminal NOTE: The piece of cable between the battery and the fuse is not protected. This is why MRBF battery mounted solutions are ideal as they are secured directly to the positive battery terminal.

Disconnect Everything:

Before starting, ensure the battery is disconnected and all loads are off.

Use the Right Tools:

Tighten connections to the manufacturer’s specified torque using appropriate tools to ensure a solid, low-resistance connection.

Use correct sized cable:

Ensure your cable cross-sectional area is suitable for the continuous enough (has a sufficient ampacity) for the fuse rating.

Secure the Fuse Holder:

Mount the fuse holder securely to prevent vibration potentially resulting in loose connections, increased resistance and increased temperatures potential causing fires.

Q: Doesn’t the BMS (Battery Management System) replace the need for the fuse?

A: Absolutely not. The BMS manages the battery’s health (controlling balancing, temperature, voltage and current limits). While LithiumPro batteries have short-circuit and over current protection built-in, they are via electronic switches that can fail in massive due very high short circuit currents. A BMS should not be used as the only layer of protection and is no substitute for a mechanical fuse. A fuse is a reliable, mechanical backup designed specifically for catastrophic faults. They are complementary layers of protection.

Q: What happens if my lithium battery fuse blows?

A: It indicates a serious fault has occurred in your system. Do not simply replace it. You must first identify and resolve the root cause, such as a pinched cable, faulty inverter, or internal short circuit. Replacing the fuse without fixing the problem will likely cause it to blow again or worse.

Q: Where is the best place to buy the right lithium battery fuses?

A: Right here! We stock a full range of high-quality Original ANL, MRBF and Class T fuses and holders, specifically selected for their high interrupt ratings and compatibility with LithiumPro batteries.

Q: Why are your MRBF fuses more expensive that the MRBF fuses on Amazon or ebay?

A: The MRFB fuses sold on market places are fake, they are dangerous copies of the OEM Original Equipment Manufactured versions. They have no certification and have not been tested to any standards. We do not recommend use of cheap fuses in any electrical system.

Q: How can i tell the difference between a quality OEM fuse and a fake copy?

A: The easiest way to tell is generally they are significantly cheaper. Always make sure you request a datasheet for the fuse. Stick to well-known brands such as Bussmann, Eaton, Blue Sea System, Littlefuse, Mersen, Siemens etc. High Quality fuses legally are required to have their ratings printed onto the fuse, their AIC values and their certification body, ie UL, or CE. A stated compliance with IEC 60269. If you do not see these marking stay away.

Q: Still unsure of how to setup your electrical system ?

A: LithiumPro offer an Off-grid System Design Service FREE to any customer that purchases our Off-Grid Systems. We can even offer a full installation service via our network of approved installers near you.

Is our free technical support program designed to assist LithiumPro customers with their battery installation. Ensuring their batteries are setup safely and efficiently to run their off-grid system. If you buy your Off-grid system from LithiumPro we offer full electrical system design and will be on hand to help support your set-up your system. We can even remotely configure your system via the VRM Portal.

If you require any further help choosing a fuse or designing you electrical system with LithiumPro batteries please contact us here

Delivery is free to all mainland UK, with the exception of NI, Scotland and the isles. Our couriers charge a small premium to delivery to these locations. This will be calculated at checkout based on your postcode.

Chat